PRODUCS

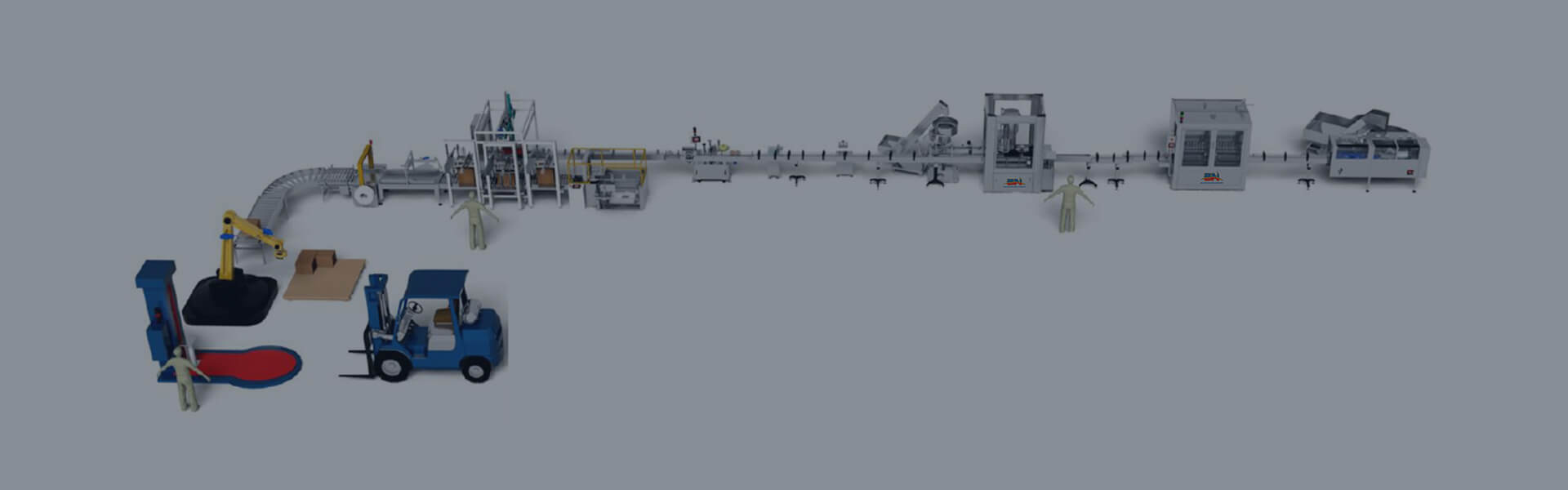

Automatic vial cap powder filling capping machine with dual-station running

This vial cap powder filling machine is customized for various auto plastic bottle or container powder filling and capping sealing production. Fully-auto & humanized design makes it stable & efficient, widely used for medical powder, cosmetic powder & food, drinks powder packaging.

Product Category:

Product Details

|

DESCRIPTION

This vial cap powder filling machine is customized for various auto plastic bottle or container powder filling and capping sealing production. Fully-auto & humanized design makes it stable & efficient, widely used for medical powder, cosmetic powder & food, drinks powder packaging.

|

MAIN FEATURES

1.With humanized, compact & reasonable design, less space taking

2.With dual-station running system, it can achieve higher capacity, stable & reliable.

3.It can finish auto cap seat unscrambling feeding, powder filling, auto top cap unscrambling feeding & pressing, auto manipulator finished caps exit etc, it only needs one labor to operate well, with highly efficiency & reliability.

4.Meticulous design & rigorous manufacturing, main parts are all from world-famous brands, the machine is very stable, reliable & durable

MAIN PARAMETERS: (PROFESSIONALLY CUSTOMIZED)

| Suitable bottle range | 5-10ml plastic caps/bottles (customized for filling capping or filling sealing based on package) | |

| Filling + capping head | 2-nozzle auger filling + 2-head cap-pressing (can be screwing or sealing based on requirement) | |

| Filling scope | 0.5mg-5g (1-10g; 10-50g) | |

| Filling error | ≤1-2% (depends on powder) | |

| Capacity | 1800-2500BPH | |

| Power supply | 220V 50/60HZ 1P | |

| Total power abt | 2kw | |

| Overall dimension | 2000*1500*1850mm | |

| Gross weight | 600kg | |

Related Products

Inquire Now