PRODUCS

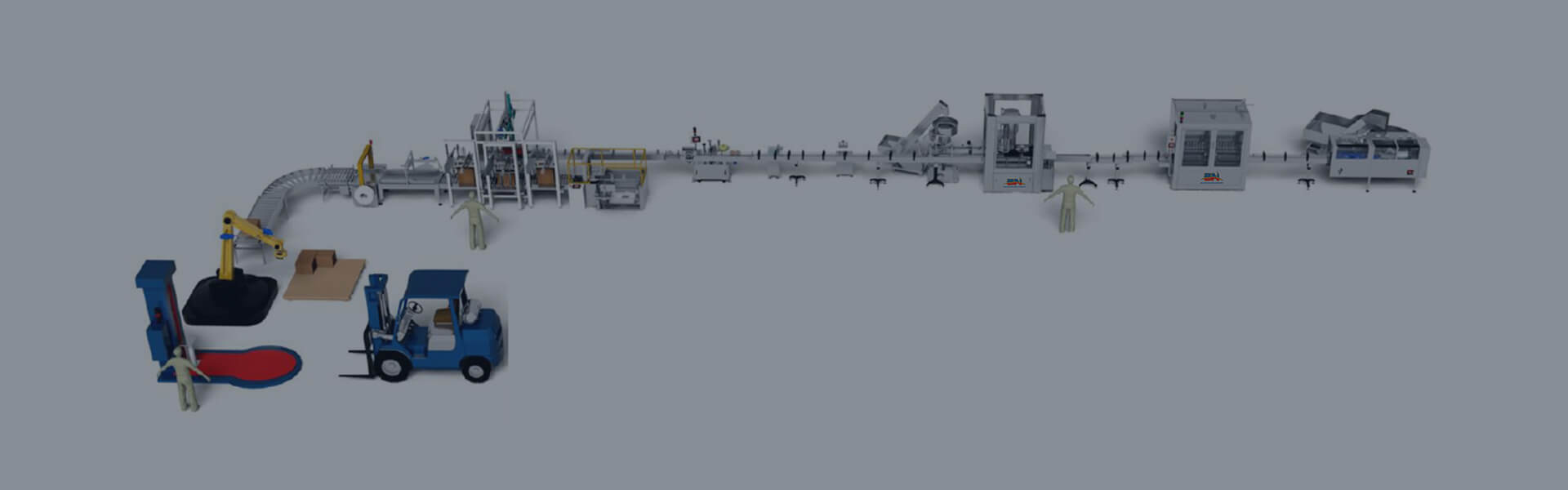

Automatic granule can filling machine with can seaming labeling line

Our automatic granules can filling machine with can seaming labeling line, adopting weighing filling, is suitable for various granules or solid filling packaging into cans, tins, plastic jars, widely used for dry seeds, nuts, granules, candy, preserved fruit canning production. It's pleasant to use & easy to maintain. Guangzhou Baoneng Machinery can supply Complete sauce ketch can filling line, can unscrambler, can washing, sterlizing, filling, seaming, labeling & printing can be professionally equipped. Welcome to contact for more.

Product Category:

Product Details

|

DESCRIPTION

Our automatic granules can filling machine with can seaming labeling line, adopting weighing filling, is suitable for various granules or solid filling packaging into cans, tins, plastic jars, widely used for dry seeds, nuts, granules, candy, preserved fruit canning production. It's pleasant to use & easy to maintain. Guangzhou Baoneng Machinery can supply Complete sauce ketch can filling line, can unscrambler, can washing, sterlizing, filling, seaming, labeling & printing can be professionally equipped. Welcome to contact for more.

|

MAIN FEATURES

1. Adopting multi-head weighing type measuring and filling, it can does accurate and fast filling with large adaptability, flexible and durable.

2. Singe-head or dual-head can seaming can be equipped based on different cans and capacity. Vaccum seaming can be equipped if needed.

3. The crimping system adopts advanced 4-head flexible seaming tech, which ensures perfect crimping/seaming effect,whole design is easy to adjust and maintaine, delicate & durable.

4. Plastic dust-cover pressing machine and round labeling machine can be optionally equipped.

5. No bottle, no filling, no seaming, no capping; with inverter speed controlling, breakdown self-detecting etc, with high automation & easy to link to filling line.

6. Made of top quality material and main parts are from famous brands, delicate, durable & reliable.

7.The filling line can be equiped with bottle unscrambling machine, washing machine, steriling machine, capping machine, labeling machine, shrinking machine, overwrapping packaging turnkey project equipment ect. It combines with mechnism, phenumatics and electrics, totally in compliance with GMP & CE production requirements, making various bottle auto production lines possible & perfect.

MAIN PARAMETERS: (PROFESSIONALLY CUSTOMIZED)

| Model | BNAPF-2000 | |||

| Filling dosage | 30-1000ml 1000-5000ml (customized based on specific size) | |||

| Weighing error | ±0.2g (depends on specific granules) | |||

| Weighing type | linear weigher, or multi=head weigher (10-head, or 14-head) | |||

| Filling nozzle | 1-nozzle lienar filling/12-station rotary filling | |||

| Capacity | 1200-1800BPH/1800-2500BPH | |||

| Plastic dust cover | auto cover feeding and pressing (optional) | |||

| Capping | can seaming/crimping | |||

| Labeling | round labeling (adhesive sticker labeling or wet glue labeling) | |||

| Voltage | 220V/380V 50/60HZ | |||

| Air pressure | 0.4-0.6Mpa | |||

Related Products

Inquire Now