PRODUCS

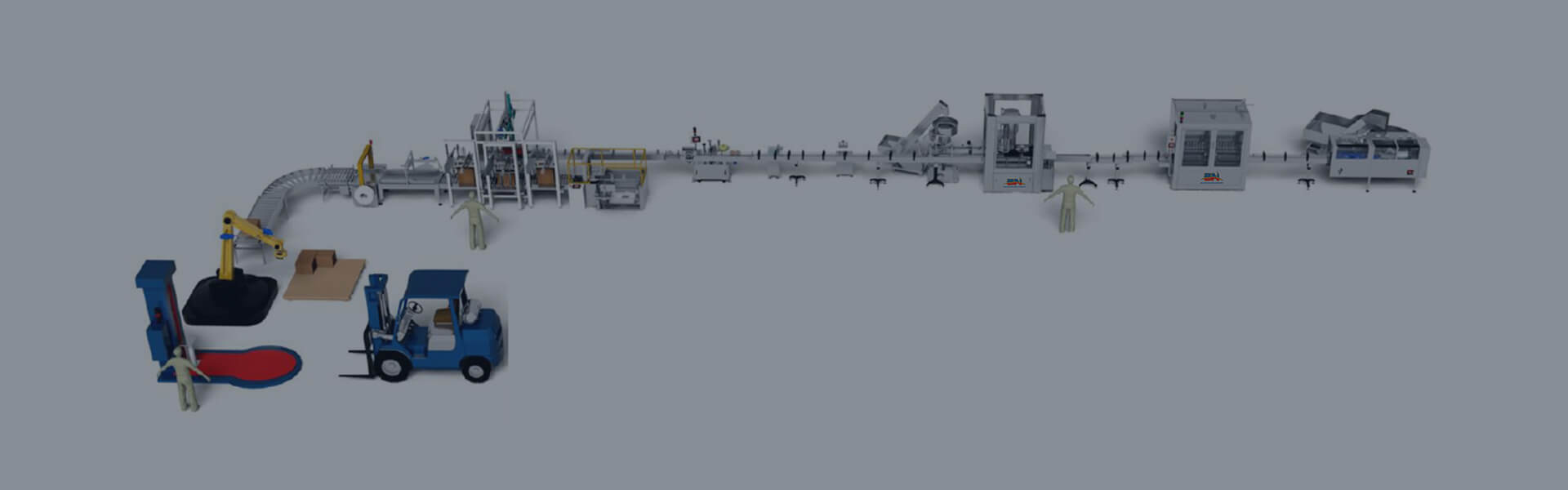

Automatic liquid detergent engine oil bottle filling line

Our automatic linear bottle sauce filling machine, adopt servo piston filling, is suitable for various yogurt, chili sauce, garlic sauce, mushroom sauce, fruit jam, ketchup bottle filling volumetric filling; with humanized design, it's pleasant to use & easy to maintain.

Product Category:

Product Details

|

DESCRIPTION

Our linear automatic liquid detergent engine oil bottle filling line , adopting servo piston filling, is suitable for various liquid, foamy liquid, cream, paste filling, ketchup bottle volumetric filling; with humanized and sanitary design, it's pleasant to use & easy to maintain. Guangzhou Baoneng Machinery focuses on various liquid/powder filling machine and relative bottle filling packaging line equipment manufacturing.

|

MAIN FEATURES

1. The servo piston filling machine is suitable for various liquid, paste & cream with or without graules inside, with large adaptability, fast speed filling & high filling precision.

2. Hot filling with mixing & CIP washing system can be equipped based on products & needs.

3. Material contacting parts mainly adopts quick-jointed connection, easy to dismantale, wash & maintain.

4. With PLC & touch screen system, with humanized design, it's easy to operate & maintain.

5. No bottle, no filling; auto counting, one button washing, inverter speed controlling, breakdown self-detecting etc, with high automation & easy to link to filling line.

6. Made of top quality material and main parts are from famous brands, delicate, durable & reliable.

7.The filling line can be equiped with bottle unscrambling machine, washing machine, drying steriling machine, capping machine, labeling machine, shrinking machine, overwrapping packaging turnkey project equipment ect.

Welcome to inquire & visit our factory in Guangzhou China. Professionally customized machines based on your needs---

MAIN PARAMETERS: (PROFESSIONALLY CUSTOMIZED)

| Model | BNAPL-2500 | |||

| Filling dosage | 100-1000ml, 1000-5000ML(customized) | |||

| Filling nozzle | 6-nozzle filling (can be 8-nzozle filling & 12-nozzle filling etc) | |||

| Filling principle | servo piston filling (can be rotor pump filling, weight filling, gravity filling, overflowing filling based on specific products) | |||

| Capping option | multifunctional capper/servo capper/linear/rotary capper | |||

| Labeller option | 2-side labeling/round labeling (film shrinking etc) | |||

| Capacity | 1800-2800BPH | |||

| Filling error | less than ±1% | |||

| Voltage | 220V/380V 50/60HZ | |||

| Air pressure | 0.4-0.7Mpa | |||

Related Products

Inquire Now