PRODUCS

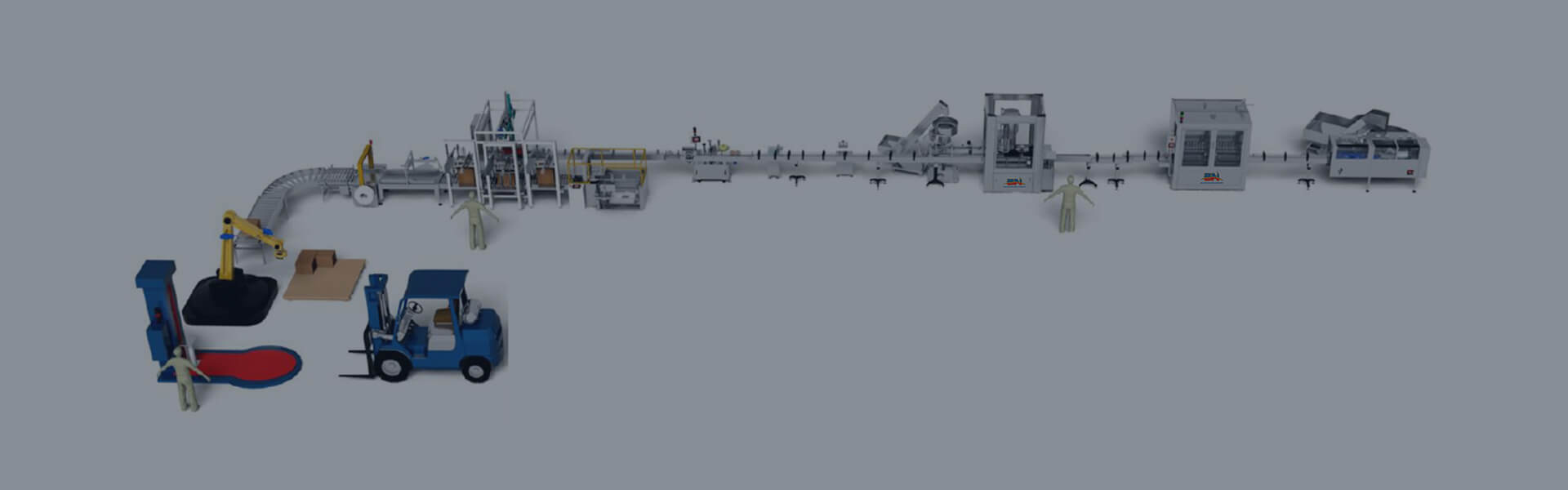

automatic liquid oil milk bottle jar filling capping labeling line

Our automatic liquid oil milk bottle jar filling capping labeling line is suitable for auto plastic/glass bottles or jars liquid filling of various light liquids, like juice, drinking tea, oil, liquid cleaner, toner, pesticide, fertilizer, alcohol etc; it can be designed with explosion proof to be suitable for liquid solvent filling, also can be anti-erosive for erosive liquids, bleach liquid, toilet cleaner and reagents filling ect, widely used in foodstuff, drinks, cosmetic, chemicals & pharmaceutical fields. Welcome to contact for professional customizing design.

Product Category:

Product Details

|

DESCRIPTION

Our automatic liquid oil milk bottle jar filling capping labeling line is suitable for auto plastic/glass bottles or jars liquid filling of various light liquids, like juice, drinking tea, oil, liquid cleaner, toner, pesticide, fertilizer, alcohol etc; it can be designed with explosion proof to be suitable for liquid solvent filling, also can be anti-erosive for erosive liquids, bleach liquid, toilet cleaner and reagents filling ect, widely used in foodstuff, drinks, cosmetic, chemicals & pharmaceutical fields. Welcome to contact for professional customizing design.

|

MAIN FEATURES

1. This liquid filling line adopts gravity filling principle, especially suitable for various light liquids or foamy liquid filling, with simple structure, cost-effectiveness and easy washing maintenance. (Fully anti-corrosive or explosion-proof gravity type filling machine are available, and we will recommend u the most suitable one based on your products & capacity)

2. Diving type anti-drip filling nozzles can be designed to meet foamy liquid filling, like milk, liquid cleaner, mouthwash, liquid pesticide etc.

3. It consists of auto bottle feeding, UV sterilizing, gravity filling, vacuum capping, round labelling, and labor packaging platform; we customize based on your production needs.

5. Whole line is mainly made from top-quality stainless steel 304 & alumi etc, main parts are from qualify brands, with stable & reliable performance, one time purchase, lifelong pleasant usage.

6. PLC & touch screen system, auto one-button washing, auto counting, auto fault alarming, easy to operate & maintain.

7.With linear bottle conveying & humanzied deisgn, it's easy to adjust for different bottles production.

8. Sanitary and CIP washing system and filling line layout can be optionally designed and equipped.

TECHNICAL PARAMETERS: (CUSTOMIZED)

| Filling nozzle | 6 nozzles (can be 8-nozzle, 10-nozzle , 12-nozzle, 16-nozzle etc) | |||

| Filling scope | 100-1000ml (100-5000ml) | |||

| capping | auto 4-head vacuum capping (can be common capping, servo capping, crimping etc, customized) | |||

| labeling | round labeling (can be side/top labeling) | |||

| Capacity | 1000-1500BPH (customized) | |||

| Filling precision | ±1% | |||

| Air pressure | 0.5~0.7MPa | |||

| Voltage & power | 380V 50/60Hz 7.5KW | |||

Related Products

Inquire Now