PRODUCS

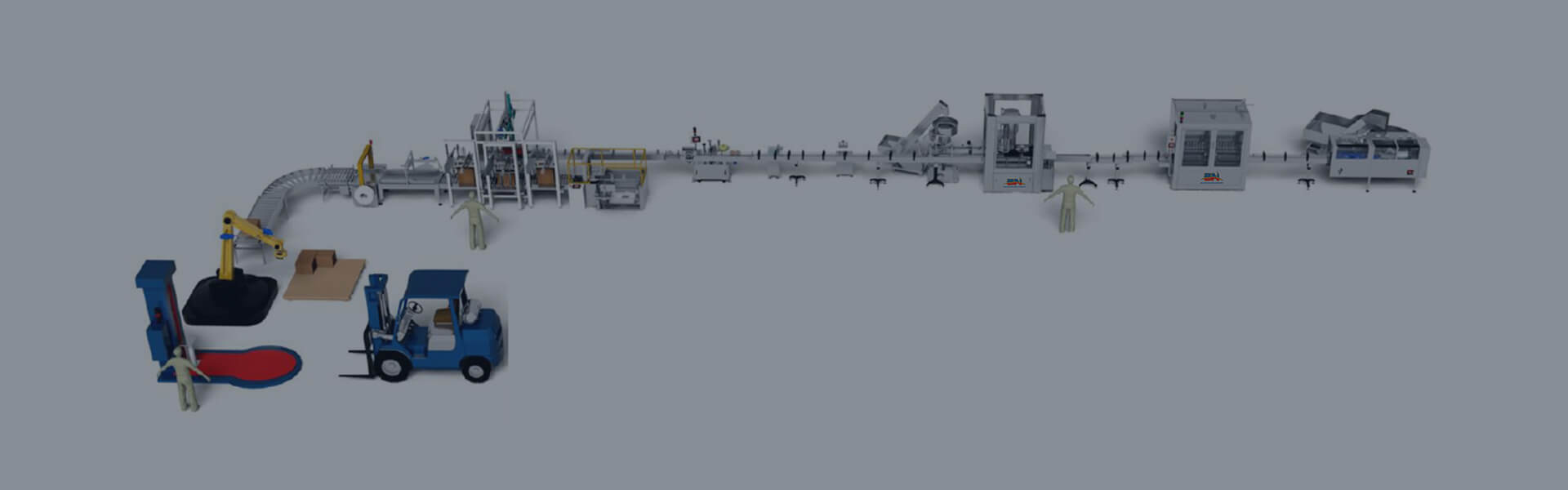

pail bottle paste oil liquid weighing filling machine with sealing capping line

1. This series of automatic paste liquid weighing type filling machine with capping sealing production line is suitable for various liquid butter sauce paste auto packaging into various barrels, jerrycans, tubs or plastic jars from 10kg to 50kg (200kg available too) etc;

Product Category:

Product Details

|

DESCRIPTION

1. This series of automatic pail paste oil liquid weighing type filling machine with capping sealing production line is suitable for various liquid butter sauce paste auto packaging into various barrels, pails, jerrycans, or plastic jars from 10kg to 50kg (200kg available too) etc;

|

MAIN FEATURES

1. This series automatic bottle weighing filling machine adopts pump (or gravity-type) to feed materials & electronic scale tech to measure the doage, and suitable for various liquid, viscous liquid, sauce and paste filling of various big bottles and buckets; with high filling precision,

2. Adopting servo conveying belt for bottle separating & positioning, it's very easy & quick to adjust for different bottles filling, economical and practical, with higher filling efficiency.

3. Adopting the scale weighing way to monitor in time the current filling quantity and feedback it to the controlling instrument, the controlling instrument outputs the controlling signal for the fast & slow filling based on the set data, realizing the fast rough filling and accurate slow filling for the fairly large filling dosages.

4. With PLC system to control & touch screen, it's easy to adjust & operate.

5. Can be equipped with servo capping, labeling, conveying machines & cartoning/palletizling based on capacity & factory layout.

MAIN PARAMETERS: (PROFESSIONALLY CUSTOMIZED)

|

Model |

BNAPL-W4 |

BNAPL-W6 |

BNAPL-W8 |

|

Filling dosage (fyi) |

0.05-1kg |

10kg-30kg |

1-5kg (customized ) |

|

Filling nozzle |

4-nozzle weight filling |

6-nozzle |

8-nozzle |

|

Capping option |

multifunctional capper /grab-type servo capper (customized based on capacity & caps) |

||

|

Labeling option |

Round or curved sticker labeling/ side sticker labeling/ top labeling (customized based on containers & speed) |

||

|

Capacity fyi |

1000-1500BPH |

400-800BPH |

1000-1500BPH |

|

Filling error |

±0.3% |

||

|

Voltage |

220V/380V 50/60HZ |

||

|

Air pressure |

0.4-0.6Mpa |

||

Related Products

Inquire Now