PRODUCS

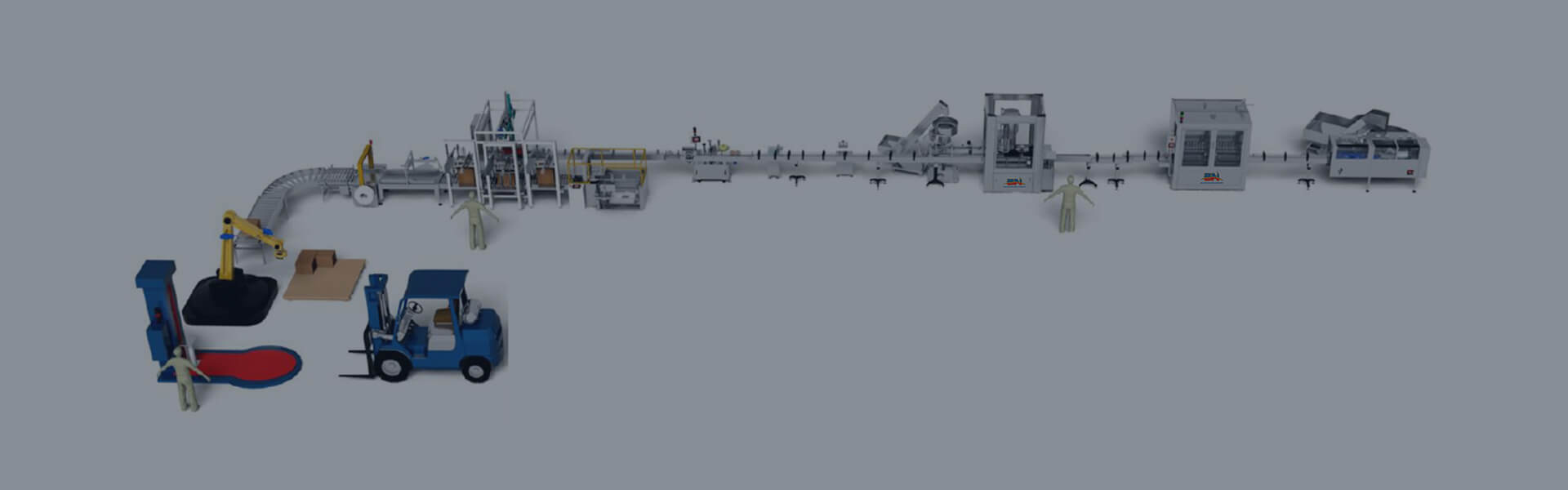

Automatic tomato paste margarine ghee can filling machine with tin washing seaming line

Our automatic margarine tomato paste can filling production line is suitable for automatic liquid paste canning of various cans & tins, widely used for tomato paste can filling production, margarine or ghee flling production, jam sauce filling production etc. It consisits of automatic can washing, can filling, can seaming, plastic lid pressing, labeling or date printing, carton packaging production, with linear & humanized design, it's pleasant to use & easy to maintain. Guangzhou Baoneng Machinery can supply Complete sauce ketch can filling line, can unscrambler, can washing, sterlizing, filling, seaming, labeling & printing can be professionally equipped. Welcome to contact for more.

Product Category:

Product Details

|

DESCRIPTION

Our automatic margarine tomato paste can filling production line is suitable for automatic liquid paste canning of various cans & tins, widely used for tomato paste can filling production, margarine or ghee flling production, jam sauce filling production etc. It consisits of automatic can washing, can filling, can seaming, plastic lid pressing, labeling or date printing, carton packaging production, with linear & humanized design, it's pleasant to use & easy to maintain. Guangzhou Baoneng Machinery can supply Complete sauce ketch can filling line, can unscrambler, can washing, sterlizing, filling, seaming, labeling & printing can be professionally equipped. Welcome to contact for more.

|

MAIN FEATURES

1. Adopting weighing type, or servo piston filling, it's is suitable for various milk, yorgurt, liquid, paste, & sauce with graules inside, with large adaptability, fast speed filling & high filling precision.

2. Hot filling with mixing & CIP washing system can be equipped based on products & needs.

3. Capping can be screwing or crimping, vacuuming capping is made based on needs.

4. With PLC & touch screen system, with humanized design, it's easy to operate & maintain.

5. No bottle, no filling; auto counting, one button washing, inverter speed controlling, breakdown self-detecting etc, with high automation & easy to link to filling line.

6. Made of top quality material and main parts are from famous brands, delicate, durable & reliable.

7.The filling line can be equiped with bottle unscrambling machine, washing machine, drying steriling machine, capping machine, labeling machine, shrinking machine, overwrapping packaging turnkey project equipment ect. It combines with mechnism, phenumatics and electrics, totally in compliance with GMP & CE production requirements, making various bottle auto production lines possible & perfect.

MAIN PARAMETERS: (PROFESSIONALLY CUSTOMIZED)

| Model | BNAPF-2000 | |||

| Filling dosage | 500-5000ml(customized) | |||

| Filling nozzle | 4-nozzle filling/6-nozzle filling | |||

| Capacity | 1200-1800BPH/1800-3000BPH | |||

| Filling error | ±0.5% | |||

| Filling way | weight filling (optional: servo piston filling or pump filling etc) | |||

| Capping | can seaming/crimping (vacuuming seaming) | |||

| Labeling | round labeling (adhesive sticker labeling or wet glue labeling) | |||

| Voltage | 220V/380V 50/60HZ | |||

| Air pressure | 0.4-0.6Mpa | |||

Related Products

Inquire Now