PRODUCS

glass vial liquid oil filling capping machine with bottle feeding washing sterilizing line

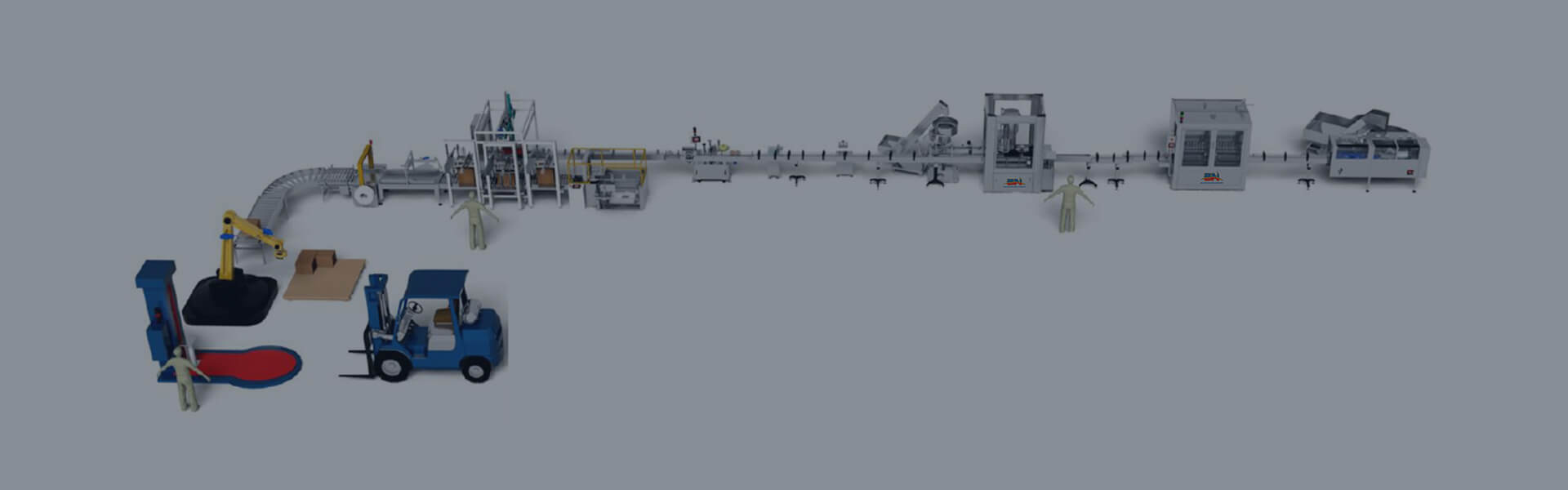

This series of automatic glass vial liquid oil filling capping machine with bottle feeding washing sterilizing line are especially designed for various glass vials or antibiotics bottles liquid filling & packaging production (can be designed for powder, granules bottle packaging too). It can auto finish bottle feeding, bottle washing, liquid filling, stoppering, cap crimping and bottle exiting, labeling etc, widely used for pharmaceutical liquid filling, cosmetic or oral products filling, greatly welcome in cosmetic & biological fields.

Product Category:

Product Details

|

DESCRIPTION

This series of automatic glass vial liquid oil filling capping machine with bottle feeding washing sterilizing line are especially designed for various glass vials or antibiotics bottles liquid filling & packaging production (can be designed for powder, granules bottle packaging too). It can auto finish bottle feeding, bottle washing, liquid filling, stoppering, cap crimping and bottle exiting, labeling etc, widely used for pharmaceutical liquid filling, cosmetic or oral products filling, greatly welcome in cosmetic & biological fields.

|

MAIN FEATURES

1. Integrated with mechanical, electrical& pneumatic system, with PLC & touch screen to control, this monoblock can auto finish bottles feeding, liquid filling, plug-feeding-pressing, cap-feeding-crimping, & bottle exiting etc.

2. With high-precision liquid pump filling, it's suitable for various pharmaceutical and cosmetic liquid gel cream filling.

Note: It can be designed with acrylic glass hood and 100-class laminar flow filter, also can be made based on specific needs.

3. With PLC & touch screen system, the filling dosage and speed can be directly controlled via touch screen, easy to operate & maintain.

4. Speed control is frequency conversion, no bottle no filling, auto counting, auto alarm faluting, with highly automation.

5. Mainly made of top-quality SUS304 material, main electrical & pneumatic parts are all from world-famous brands, machines are delicate & durable.

6. Optional bottle water washing, heat drying sterlizing & bottle labeling, cartoning etc; Baoneng Machinery supplies u professional cost-effective high-performance filling line machines.

MAIN PARAMETERS: (PROFESSIONALLY CUSTOMIZED)

| Model | BNAFC-R1 | BNAFC-R2 | |

| Working station | single-station running (1 vial/time) | dual-station running (2 vials/time) | |

| Filling dosage | 1-10ml glass vials (10-200ml) | 1-10ml glass vials (10-200ml) | |

| Filling/stopper/capping head | 1-head vial filling plugging crimping | 2-head vial filling plugging crimping | |

| Filling error | ≦±1% | ≦±1% | |

| Capacity | 1500-1800BPH (based on 10ml) | 2500-3000BPH (based on 10ml) | |

| Power supply | 220V 50/60HZ 2.5KW | 220V 50/60HZ 3.5KW | |

| Filling way | ceramic pump filling, peristaltic pump filling, piston filling, gear pump filling etc (can be powder & granules filling design too) | ||

| Optionally | bottle feeder, bottle washing machine, bottle sterilizing machine, bottle labeling machine, bottle seaking, cartoning machine etc | ||

Related Products

undefined

Inquire Now