PRODUCS

Automatic servo pump liquid paint oil filling machine for bottles cans jars

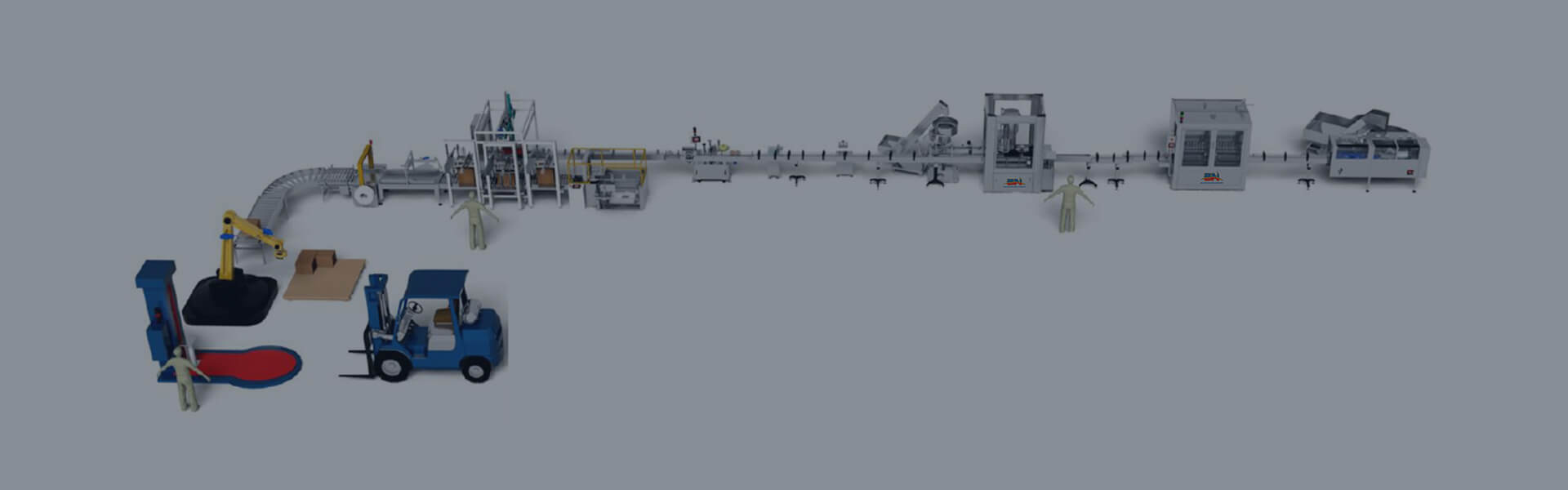

Our automatic servo pump liquid paint oil filling machine for bottles cans jars, adopting servo gear pump or rotor pump filling, it is suitable for various liquid, viscous liquid, cream & paste bottle filling; the simple structure makes aseptic filling & easy maintenance, widely used for foodstuffs, drinks, cosmetics, pharmaceuticals, daily chemicals product packaing production, like oil filling, liquid detergent filling, paint filling, oil filling, jam sauce filling, juice drink filling, honey filling, liquid cleaner filling etc.

Product Category:

Product Details

|

DESCRIPTION

Our automatic servo pump liquid paint oil filling machine for bottles cans jars, adopting servo gear pump or rotor pump filling, it is suitable for various liquid, viscous liquid, cream & paste bottle filling; the simple structure makes aseptic filling & easy maintenance, widely used for foodstuffs, drinks, cosmetics, pharmaceuticals, daily chemicals product packaing production, like oil filling, liquid detergent filling, paint filling, oil filling, jam sauce filling, juice drink filling, honey filling, liquid cleaner filling etc.

|

MAIN FEATURES

1. Adopting servo rotor/gear pump to do measuring, suitable for both liquids, gel, paste & cream, with wide application, high filling precision & filling efficiency;

2. Filling nozzle can be servo system for diving type filling, suitable for variouis foamy liquids & unfoamy products.

3. Filling volume & speed can be adjusted directly via touch screen, easy to operate & maintain.

4. With humanized design & pump filling, all filling parts are quick-joint connected, meeting aseptic filling, easy to dismantle, wash & maintain; very stable & durable, no damage & pollutiion to materials.

5. Linear bottle-enter-exit, it is easy & quick to adjust whole system to meet different bottles production.

6. PLC control system & touch screen operation panel; no filling without bottles; auto counting, one-button washing, with high degree of automation.

7. Auto liquid processing mixing equipment & auto capping labeling packaging line equipment are available, welcome to inquire for one-stop service and purchase.

Filling type available from us: piston type filling machine, weighing type filling machine, servo auger filling machine, backflowing filling machine, gravity filling machine,

gear/rotor/peristaltic pump filling machine, volumetric cup filling machine, flowmeter filling machine, negative filling machine etc,

We can do them as linear machine & rotary intermittent machine, rotary continuous machine based on specific bottles, material & capacity etc; welcome to contact for best solutions & most suitable machines!

TECHNICAL PARAMETERS:(CUSTOMIZED)

| Filling type | BNAPF-RP8 | BNAPF-RP4 | |||

| Filling scope | 100-1000ml | 1000-5000ml (customized) | |||

| Filling nozzle | 8-nozzle | 4-nozzle(can be 6-nozzle, 10-nozzle etc) | |||

| Capping choose | highspeed capper upto 5000BPH | universal cap screwing/pressing | |||

| Capacity | 2500-4000BPH | 1000-2500BPH | |||

| Filling error | ≤ ±1% | ≤ ±1% | |||

| Voltage | 220V 50/60HZ 9.5KW | 220V 50/60HZ 5.5KW | |||

| Air pressure | 0.5-0.7Mpa | 0.5-0.7Mpa | |||

Related Products

Inquire Now