PRODUCS

Automatic 2-head bottle powder filling machine with explosion proof design

Adopting servo auger & weight filling to do powder measuring and filling, this automatic bottle powder filling machine is suitable for various powder bottlee, jar or pail filling packaging, widely used for various powder bottle packaging, like nutrient powder filling, drink powder filling, pesticide powder, pharmaceutical powder & chemical powder etc. Explosion-proof design can be made accoridngly based on needs.

Product Category:

Product Details

|

DESCRIPTION

Adopting servo auger & weight filling to do powder measuring and filling, this automatic bottle powder filling machine is suitable for various powder bottlee, jar or pail filling packaging, widely used for various powder bottle packaging, like nutrient powder filling, drink powder filling, pesticide powder, pharmaceutical powder & chemical powder etc. Explosion-proof design can be made accoridngly based on needs.

|

MAIN FEATURES

1. Adopting two-time powder filling, 1st servo auger tough filling, and 2nd weighing type filling for accurate filling, optionaly equipped with vacuum or spiral auger to do auto owder feeding, it can meet auto continuous production of various powder bottling, with high filling precision & production efficiency.

2. With vibrating device to make sure even filling & better cap-pressing effect.

3. With PLC & touch screen to control, formula saving, auto counting function, no bottle, no filling; frequency converter, with high automation.

4. With humanized design, it's easy & quick to change and adjust for bottles production with different sizes.

5. Electrical & pneumatic parts adopts the world-famous brands, like Delta, Airtac & Schneider; it has the incomparable advantages of low failure rate, stable and durable

6. Mainly made of top-quality stainless steel 304, easy to maintain, delicate& durable.

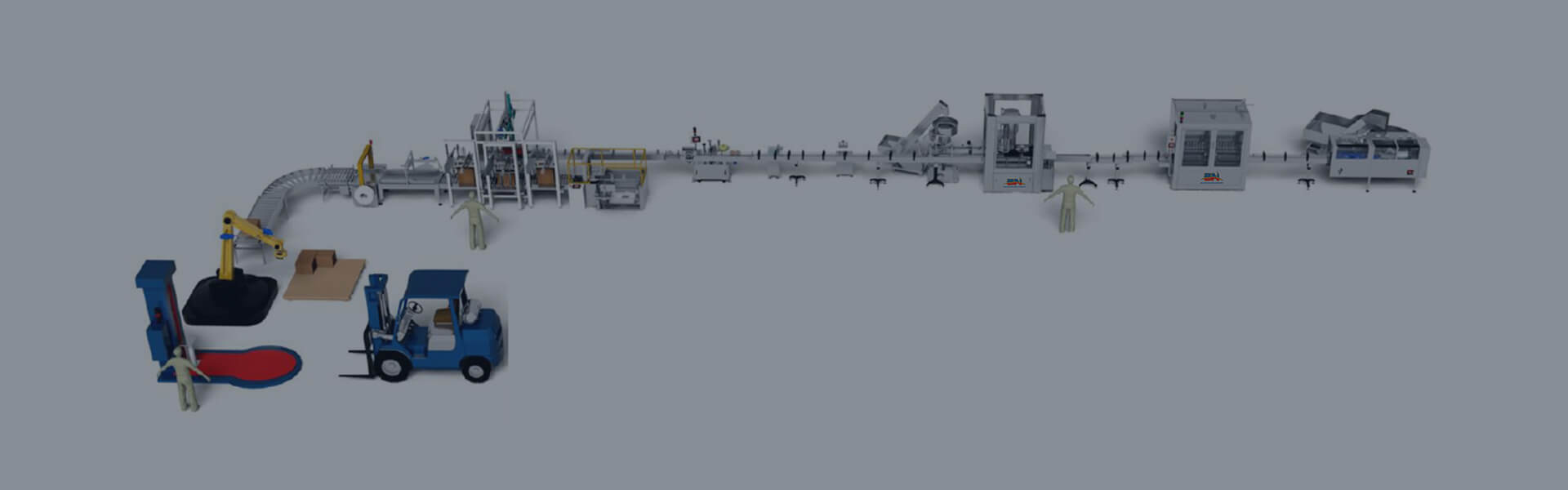

7. Auto capping, labeling, date printing, wrap packaging can be professionally supplied based on production requirements.

MAIN PARAMETERS: (PROFESSIONALLY CUSTOMIZED)

| Filling scope | 0.5-5kg(customized 0.1-10g, 10-100g; 100-1000g etc) | |

| Speed | 600-1000 pcs/hour (customized) | |

| Electric consumption | 2kw; 220V 50Hz 1P | |

| Suitable bottles | Plastic/metal bottles/jars/cans | |

| optionally | bottle unscrambler, capper, labeller, cartoner etc | |

| Working pressure | 0.5-0.7Mpa | |

| powder feeder | Pneumatic vacuum powder or samll granules feeding (optionally sprial auger feeder) | |

| Filler dimension | L2050mm*W1350mm*H1900mm | |

| Weight | 800kg | |

Related Products

Inquire Now