PRODUCS

Quality 8-nozzle liquid cleaner disinfectant servo piston filling machine for foamy corrosive liquids

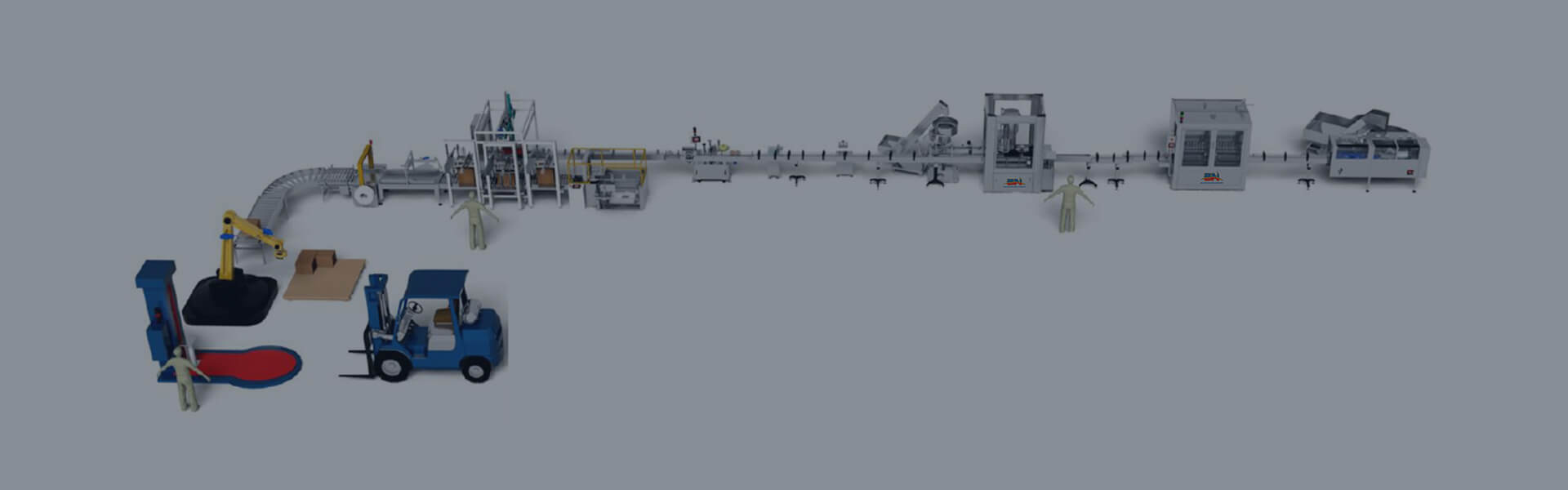

DESCRIPTIONBaoneng quality 8-nozzle liquid cleaner disinfectant servo piston filling machine for foamy corrosive liquids, adopting servo piston type measuring & servo nozzles filling, with high filling precision and flexible filling scope, which can effective decrease foams, it's suitable for auto bottle packaging of various liquid, foamy liquids and corrosive liquids filling, like bottle filling of cosmetic liquid, liquid cleaner, mouth wash, pesticide, pharmaceutical liquid, disinfectant, sodium hydroxide etc;.

Product Category:

Product Details

|

DESCRIPTION

Baoneng quality 8-nozzle liquid cleaner disinfectant servo piston filling machine for foamy corrosive liquids, adopting servo piston type measuring & servo nozzles filling, with high filling precision and flexible filling scope, which can effective decrease foams, it's suitable for auto bottle packaging of various liquid, foamy liquids and corrosive liquids filling, like bottle filling of cosmetic liquid, liquid cleaner, mouth wash, pesticide, pharmaceutical liquid, disinfectant, sodium hydroxide etc;.

|

MAIN FEATURES

1. Adopting servo piston to do measuring, suitable for both liquids, gel & cream, with high filling precision & filling efficiency; plus servo filling nozzle system, it's especially good for some foamy products accurate filling.

2. Filling volume can be adjusted directly via touch screen.

3. With humanized design, piston cylinders are quick-joint connected, easy to dismantle, wash & maintain.

4. Linear bottle-enter-exit, it is easy & quick to adjust whole system to meet different bottles production.

5. PLC control system & touch screen operation panel; no filling without bottles; auto counting, one-button washing, with high degree of automation.

6. Auto liquid processing mixing equipemnt & auto capping labeling packaging line equipment are available, welcome to inquire for one-stop service and purchase.

TECHNICAL PARAMETERS:(CUSTOMIZED)

| Model | BNAPL-8 | BNAPL-12 | |||

| Filling scope | 100-1000ml (customzied 500-5000ml) | ||||

| Suitable material | various liquids, foamy liquids without granules; (optional for cream, sauce, gel etc) | ||||

| Filling nozzle | 8-nozzle (option 4/6-nozzle) | 12-nozzle (option 10/14-nozzle) | |||

| Capping option | universal/servo capping | linear/rotaryhigh speed capping | |||

| Capacity | 2000-2500BPH | 3000-3500BPH | |||

| Filling error | ≤ ±1% | ||||

| Voltage | 220/380V 50/60HZ 3KW | 220/380V 50/60HZ 4KW | |||

| Air pressure | 0.5-0.7Mpa | 0.5-0.7Mpa | |||

Related Products

Inquire Now